Air Compressor Audit

Measuring Performance of Installed Air Compressors

Measuring the Free Air Delivery (FAD) of an air compressor can be challenging. With a proper flow meter and some mathematics, this task is manageable.

To produce compressed air by sucking in ambient air, pressurizing or compressing it, and discharging it into the compressed air network is the ultimate job of an air compressor. Air compressor power is defined by its power rating and the FAD specifications stated by the manufacturer when new. However, as time goes by, an on-site measurement can be very useful. There are several simple questions, which eventually explain the performance of an air compressor:

- How much electrical power is my air compressor consuming?

- How much electrical power is my air compressor consuming?

- What's my pressure profile?

- Temporary performance measurement, done as part of system assessments, or before investing in a new air compressor.

- Permanent performance measurement, which is performed to monitor the performance at all times in order to trigger services or overhauls timely.

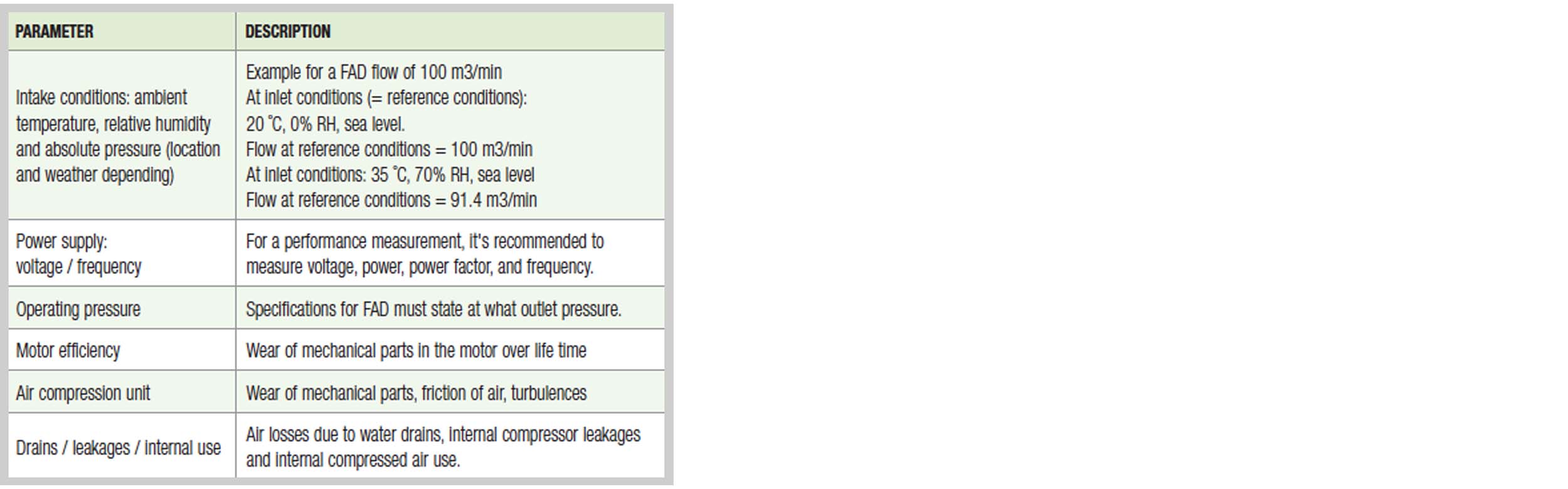

There are a couple of parameters that affect the efficiency of air compressors.

As PNEUMSYS is regularly executing audit services for reciprocating and screw compressors both for lubricated and non lubricated compressors.

A sample audit report of an actual project is available for download below.

The privacy and confidentiality of the client has been obscured to protect their identity for obvious reasons.

Sample Audit Report More Info

Download Catalogue