Godrej ControlAiR™ IFC - Demand Side Management Solution, is the revolutionary energy saving solution in the field of compressed air system. By introducing a controlled differential pressure across an upstream receiver and itself, IFC creates useful storage. This storage isolates the compressors from demand side fluctuations. Peaks are dealt with using the reserve energy in storage instead of additional horsepower, allowing the compressors to run on reduced load. Thus by providing air at a controlled differential and at an optimum pressure to the plant, the mass of air consumed by pneumatic equipment, tools & leakages is reduced which in turn results in reduction in energy consumed by air compressors. We have 4000+ installations of Godrej ControlAiR™ IFC worldwide. We have received National Award from Confederation of Indian Industry (CII) for Godrej ControlAiR™ IFC as "Innovative Energy Saving Product".

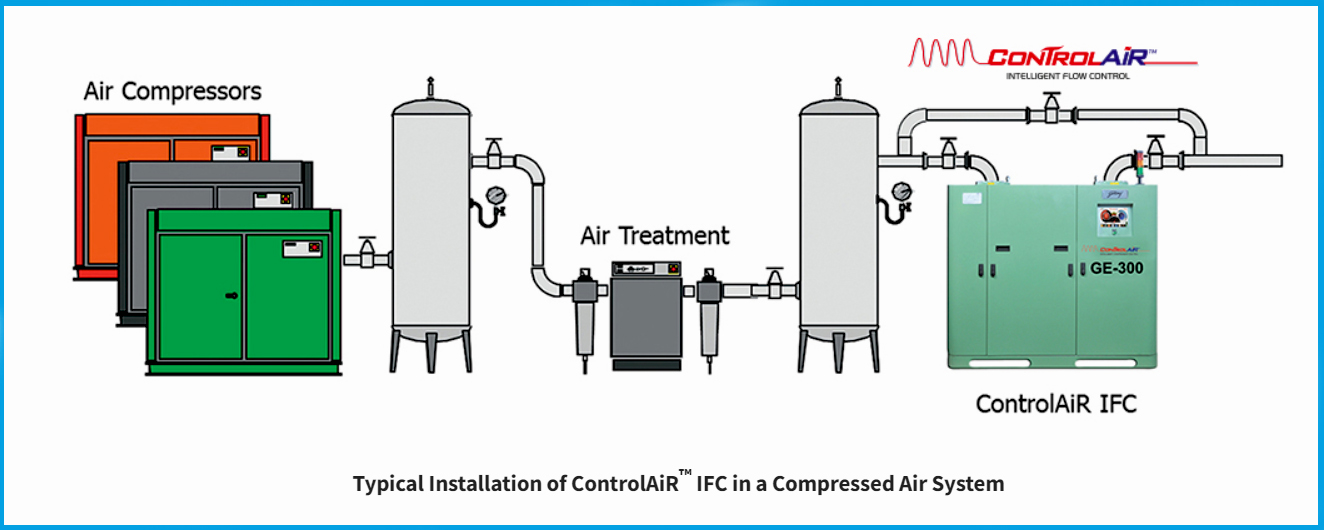

By controlling the air flow and pressure being delivered to the plant, ControlAiR Intelligent Flow Control System (IFC) reduces artificial demand. It is designed to operate at an intermediate point i.e. on the downstream side of the air treatment equipment and upstream side of the main piping distribution system.

The mass of air consumed by pneumatic equipment, tools & amount of leakages is reduced since ControlAir IFC provides air at a controlled differential and optimum pressure, ultimately resulting in the reduction in energy consumed by Air Compressors.

Why There Is An Opportunity For Energy Saving?

Every industry has problem of fluctuating air pressure. This is caused by intermittent use of several pneumatic equipments. It begins with sudden air demand pulling down pressure at the point of use. The only way for the Air Compressors to know about it, is when it travels to upstream through distribution network. The capacity control mechanism of the Air Compressor in the form of Load/Unload or VSD then starts delivering compressed air in the system. Practically it takes a while for the entire air system to fill up to the required pressure.

Benefits:

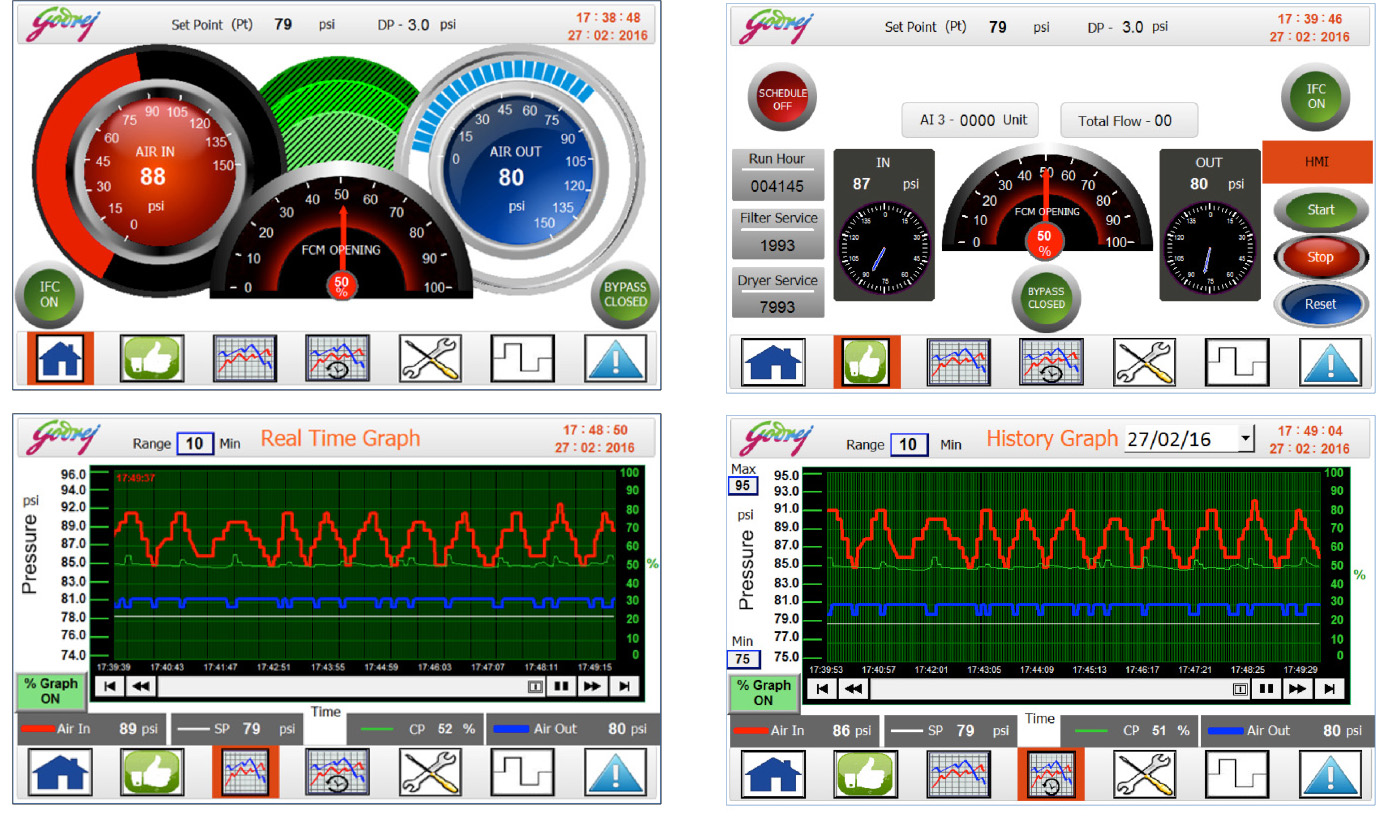

ControlAir IFC is user friendly with HMI Touchscreen Colour Graphics Display showing multiple screens to exhibit following information.

IFC – Downstream Controller:

- IFC is designed specifically to operate at intermediate point of the compressed air system i.e. on the downstream side of the filter/ dryer/ receiver and upstream side of the main piping distribution system.

UPC – Upstream Controller:

- UPC maintains reduced constant upstream pressure in compressed air system.